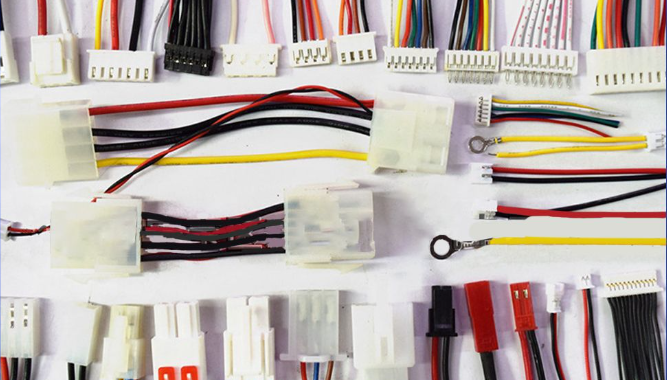

The processing of terminal lines requires a multi-channel technology, and Changjing Electronics boasts a comprehensive and impeccable quality management system. To enhance your understanding of terminal lines, allow me to present the key points that require attention in our company’s processing of these lines.

First, after pressing the terminal line, it is necessary to manually wear the rubber shell. It should be noted that this step cannot be automated and must be done correctly to ensure that the rubber shell is securely in place and will not fall off.

Second, the terminal line shall undergo a thorough inspection by the quality department post-processing, with any non-conforming products being subject to rework.

Thirdly, it is imperative to ensure the accuracy of incoming materials for the terminal line, conduct thorough inspections on raw materials, and take measures to prevent production scrap at its source.

Last, after verifying the material of the terminal wire, it is necessary to cut and crimp the wire. It is recommended to use the first piece as a reference for subsequent production and inspection.

From the suppliers selection, Raw material inspection, pre-production risk control, Quality control of each step in the whole product process to the full test for the finished products, Changjing have very strict policy and Guidance documents, so you should never worry about our product quality.

Being a factory specialized in terminal line and wire harness more than 10 years, we provide one stop solution for your any custom project. As a factory, we are always looking for the long term business with our clients, never the one time dealing, so you are assured with our sincerity for cooperation.

Post time: May-30-2023